The Design and set up of tooling for rotary draw bending

Typical Example:

- 2.0″ O.D. x .065″ wall on 4″ center line

- Wall factor 30 – 2 x “D” of bend

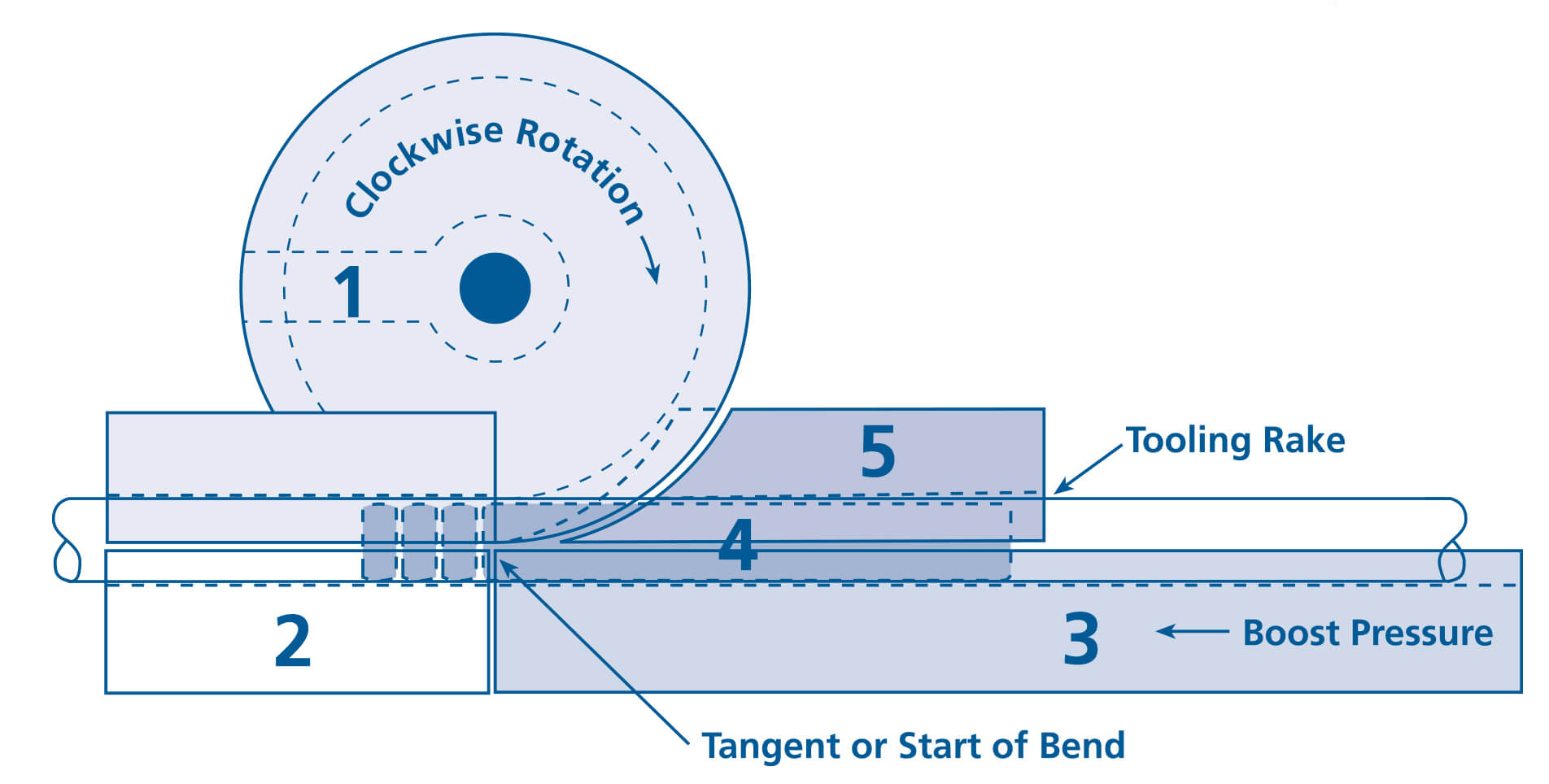

1. Bend Die

- Hardened tool steel or alloy steel, heat treated and nitrided

- Clamp insert is secured with cap screws and dowel pins

- Drive key must be parallel to clamp insert

- Bore should have a slip fit over centering ring or spindle

Note: Bend dies may have special tube grooves with captive lip or Empty Bending

2. Clamp Die

- Hardened tool steel or alloy steel, heat treated and nitrided

- Preferable length is 3 X tube O.D.

- Tube groove is grit blasted or may be serrated if less than preferred length

- With tube held in bend die, advance clamp die and adjust for vertical alignment

- Adjust for parallel contact with entire length of clamp

- Adjust for pressure

3. Pressure Die

- Alloy steel and nitrided

- Tube groove must be parallel to back of die

- If follower type pressure die is used, length equals 180 degrees + 2 O.D.

- If a boosted system is used, groove should be grit blasted

- With tube clamped to bend die, advance pressure die and adjust for vertical alignment

- Start with minimal pressure and increase as required in small increments

4. Mandrel

- Type of mandrel and number of balls indicated by Tooling Selection Guide

- Aluminum/Bronze, chrome, or Kro-Lon mandrels for ferrous tubing. Only chrome mandrels for non-ferrous

- Gain best results with most mandrels when shank projects a small amount past tangent (bend and try)

- Lube I.D. of each tube

5. Wiper Die

- The Tooling Selection Guide indicates when a wiper may be required

- Push tube over properly located mandrel and bring clamp and pressure dies up to bending position

- Slide wiper along tube as far as possible into bend die then secure to holder

- Unclamp pressure and clamp dies, tip of wiper should be “very close” to tangent

- Adjust for rake and vertical alignment

- Lube each tube and the wiper